|

|

The Glassware Gallery

The Glassware Gallery

For routine laboratory operations, ground glass stopcocks should be coated with silicone grease. Using your finger, rub the grease evenly around the glass plug and then insert it into the stopcock. Push in and turn the stopcock back and forth a little bit. You should not see any streaks and the joint will no longer look opaque. Make sure the bore in the plug lines up with bore in the sidearms. If not, then find another plug.

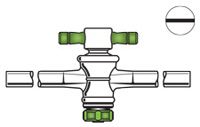

Glass plugs are usually held in place by a green metal clip (on the right in the drawing above). These clips fit into a slot on the protruding end of the plug and keep the plug from popping out of the stopcock. People sometimes find these clips rather confusing, but they are really quite easy to use. To install a clip, compress the prongs and slide the clip into the slot on the plug with the wider side of the clip facing away from the stopcock. The tension of the clip trying to spring apart holds the plug in place.

Simple Teflon stopcocks do not require any grease. However, it is important to assemble these in the correct order as shown in below on the right. First install the plug and then put on the Teflon washer, Viton O-ring and nut. Tighten the nut with your fingers, but not so much that the stopcock can not turn easily. Take care not to strip the threads on the plug. A common misconception is that the O-ring provides a leak-proof seal. This is actually accomplished by the Teflon washer -- the O-ring actually controls how hard it is to turn the stopcock.

Important: Glass high vacuum stopcocks are matched to their plugs. You can not interchange the plug from one high vacuum stopcock with another -- the match may be close but it will not be perfect. To prevent accidental mix-ups, both the plug and the stopcock have a number etched or painted on them. If you break the plug, you should consult with your glassblower on what to do.

Safety Emporium carries faucets and valves in addition to stopcocks.

Teflon(tm) stopcocks are much easier to open a small amount than those shown above because they turn on and off like a faucet. Some have specialized tips and bores to allow very fine flow control ("needle valves"). Teflon stopcocks come in a variety of configurations as shown below:

Safety Emporium carries replacement valves and stopcocks.

Teflon(tm) does not need to be greased, but the O-rings on the shaft of the plug should be treated with an extremely thin coating of grease. A good way to do this is to simply rub your nose with your thumb and forefinger and then rub the O-ring (honest. No kidding). Alternatively, Apiezon M grease is a good choice. This will make the shaft slide into the barrel quite easily and will make turning the stopcock even easier.

NEVER FORCE A TEFLON(tm) STOPCOCK If the shaft won't catch the threads and start turning it is either damaged, misaligned, the wrong size or the O-rings were not greased. Forcing the stopcock will either strip the Teflon(tm) threads or shatter the glass barrel of the stopcock.

![]()

This page was last updated Sunday, June 12, 2016.

This document and associated figures* are copyright 1996-2025 by Rob Toreki. Send comments, kudos and suggestions to us via email.

*Some of these figures are adapted from the Chemglass, Inc. catalog and have been reproduced with permission.