|

Safety Emporium is a proud sponsor of this site. |

|

Home Page --> Tutorial Lesson 5, Burners and Torches

|

|

Safety Emporium is a proud sponsor of this site. |

|

Home Page --> Tutorial Lesson 5, Burners and Torches

|

| Tutorial Lesson 5, Burners and Torches | |

|---|---|

| Lesson 4 (Oxygen and Fuel Gas Systems) |

Lesson 6 (Cutting Glass) |

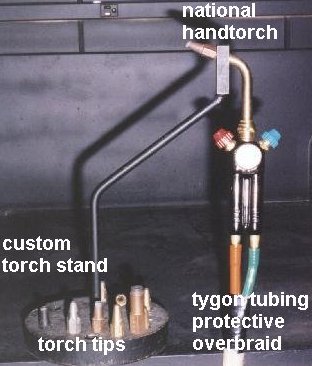

Pre-mix torches as a rule are capable of burning a little hotter with a flame that can be very concentrated. Gas and oxygen are mixed in a chamber within the torch body. This style torch is preferred when making seals and/or when heating small concentrated areas. If you were to be restricted to using only one torch, the pre-mix is recommended. Premix torches have the benefit of having interchangeable tips, allowing the user the option of changing flame characteristics over a broad range. A torch used quite extensively in the industry is the National Handtorch Type 3A Blowpipe shown here. This relatively inexpensive torch, with tip sizes #2, 3, 4,and 5 will cover most of your needs.

Surface-mix torches and burners are used most frequently when large areas of glass need to be worked. Oxygen and fuel gases are mixed at the torch tip. The flame characteristics tend to be broader and softer, with less velocity than a comparable sized flame from the pre-mix torch. This is a good torch to use when preheating a large piece of glass apparatus for repair, or when shaping large tubing. An excellent example of a burner that incorporates surface-mix and pre-mix capabilities would be the Carlisle CC Burner.

There are many other makes and models of burners and torches available to the glassblower. Their different flame and body characteristics determine their application in the glassblowing field.

Torches (handheld) may be used as burners by simply hanging or attaching them to some sort of fixture. This fixture may be something as simple as a ring-stand and clamp assembly or a custom made unit that will hold the torch in a safe and secure manner.

Review all safety procedures before you plan or start your work. Think out what it is that you will be doing and know what action to take if something happens different than expected. Read through the instruction text to prepare for the exercise. It is best to avoid surprises at this stage of instruction!

| Tip: If you experience difficulty in immediately igniting the gas beware of excessive gas buildup. Shut the gas valve off and wait a few minutes to allow the gas to dissipate. Attempt to light the torch again using a different setting on the gas valve. |

| Tip: Take the time to become comfortable handling your torch now. With practice, creating the various flames necessary to produce sound glassblowing seals will become second nature |

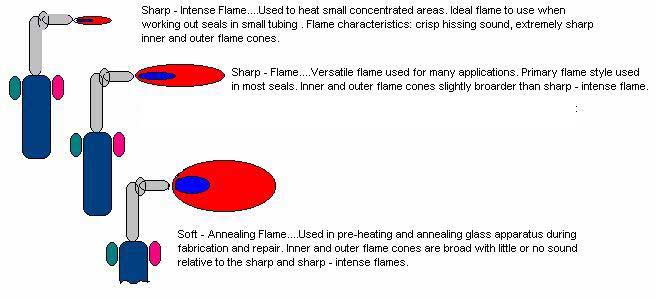

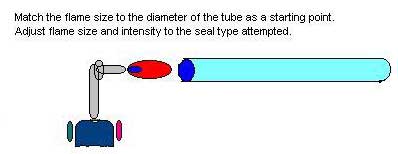

Flame intensity is a factor in determining how quickly the glass reaches working point temperatures. Experience will guide you in choosing the proper flame intensity and flame size to apply to the different types of seals. Each person will develop their own style and technique in using the torch. The information presented here should serve as a starting point.

| Tutorial Lesson 5, Burners and Torches | |

|---|---|

| Lesson 4 (Burners and Torches) |

Lesson 6 (Cutting Glass) |

This page and any associated material is copyright 2002-2025 by Joe Walas and/or ILPI unless otherwise stated. Unauthorized duplication or posting on other web sites is expressly prohibited. Send suggestions and comments (include the URL if applicable) to us by email. CAUTION: Be sure to read this important safety/legal disclaimer regarding the information on this page.