|

Safety Emporium is a proud sponsor of this site. |

|

Home Page --> Glass Workshop Tour

|

|

Safety Emporium is a proud sponsor of this site. |

|

Home Page --> Glass Workshop Tour

|

The main glassworking workbench (below, left) features a line of sight to the room entrance which permits customer interaction without having the customer enter a potentially hazardous area.

The student glassworking benches (below, right) have ample separation for safety and allow for open communication and observation between students and instructor, regardless of where he/she may be in the shop.

The sink area features a 5 foot stainless steel sink that can accommodate the 4 foot lengths of tubing commonly used by glassblowers. The faucet and drain are at the end of the sink to maximize their usefulness.

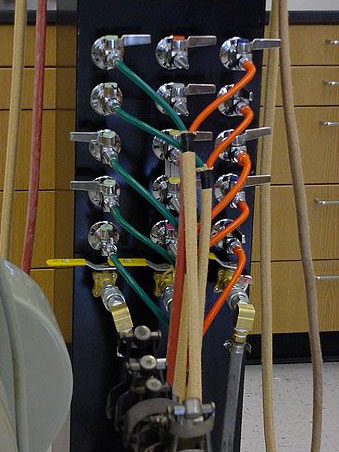

The sink area features a 5 foot stainless steel sink that can accommodate the 4 foot lengths of tubing commonly used by glassblowers. The faucet and drain are at the end of the sink to maximize their usefulness.Hot, cold, and distilled (DI) water are available and sources of compressed air and vacuum are nearby. The hand-held safety eyewash doubles as a handy rinse hose. The deep sink depth is based on personal preference; others may prefer a shallow basin. Adjacent to the sink are standard countertops long enough to serve as work or prep areas for pre- or post wash operations.

There is a canopy hood (not shown) directly over the sink to aid in chemical fume removal.

I've found that with only two hands to hold onto soapy (and slippery) glassware, foot operated on/off water valves are the way to go.

How much lighting is enough - or too much? Natural light conditions are controlled by window placement and exposure (if you have windows), and will change with the time of day or season of year. This lighting can be confusing to the student through excessive light reflection or glare directly on the glass being worked or onto the work surface area. Manually controlled adjustable lighting can help eliminate these problems. The left photo illustrates the use of indirect lighting to lessen glare. Open a second control switch and the lights function "normally".

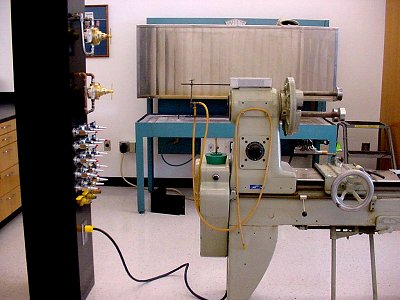

Do you want a closed or open ceiling? How about canopy hood? While much can and will be said about the use of open canopy exhaust hoods mounted directly over the glassblowers work bench or lathe, I'm of the opinion that canopy hoods may not be necessary in the university research shop. Many university research glassblowing operations do not operate under the same conditions as the private sector production facility. The university/research glassblower may spend as much (if not more) time in consultation and design as in the act of glassblowing itself. Heat and chemical releases from the glassblowing process will usually be much less than what is found in the production shop.

In many situations, a properly balanced air handling system with an appropriate number of room air changes as determined by law and/or your facility EH&S and HVAC experts will be more than adequate. Using the open ceiling approach will in effect give you the entire upper room as your canopy to collect the heated air and gases for removal through normal air exchanges. One does need to be aware of air diffuser placement, orientation and operation, however. Air drafts over the hot working areas should be avoided.

In this particular facility we opted to have a suspended (closed) ceiling over the entry, administrative and student bench areas. This was done for aesthetic reasons and the look was in harmony with the other laboratories and office areas on the floor. The rear of the glassblowing facility, where most of the glassblowing takes place, has an open ceiling.

The casework shown in the right photo right serves as a barrier separating the student benches and customer service area from the main shop. The width/separation is intentionally deep at 5-1/2 feet. Glassware coming in for repair is staged here, minimizing customer and student exposure to sharp and broken glassware. Ample storage of glass parts is provided here and elsewhere in the shop.

This page and any associated material is copyright 2002-2025 by Joe Walas and/or ILPI unless otherwise stated. Unauthorized duplication or posting on other web sites is expressly prohibited. Send suggestions and comments (include the URL if applicable) to us by email. CAUTION: Be sure to read this important safety/legal disclaimer regarding the information on this page.